Shafae Developing Sensors to Improve 3D Printing Process

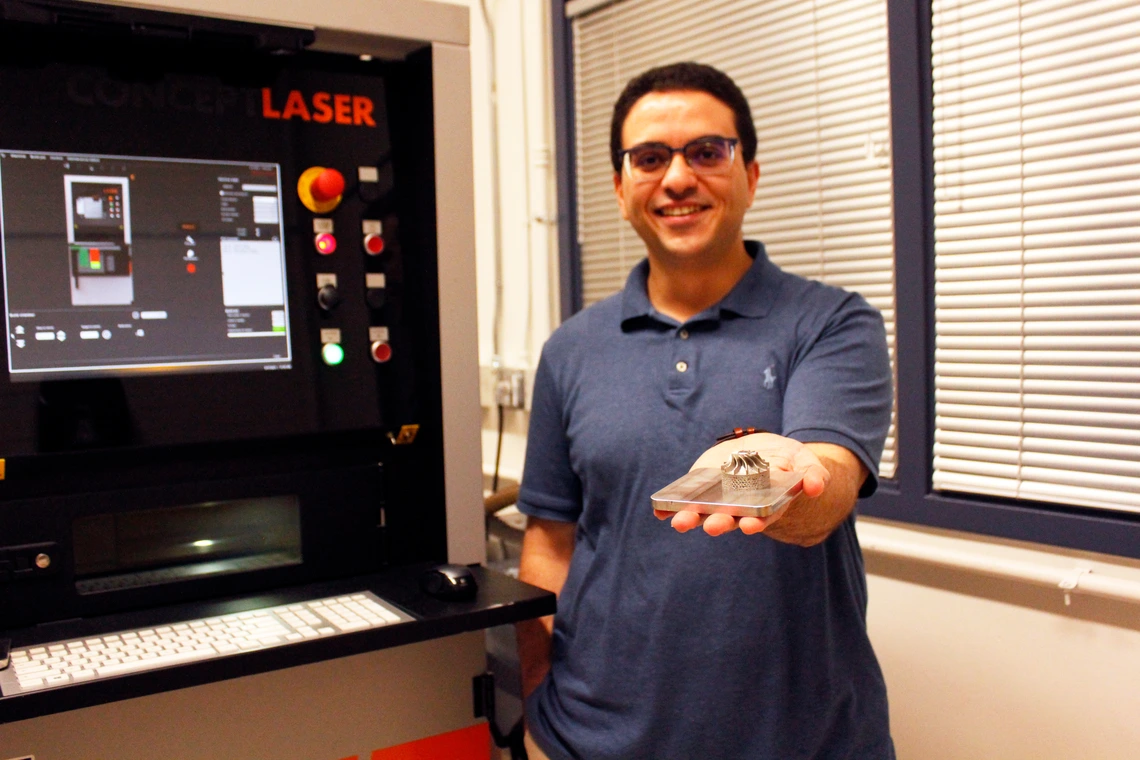

SIE assistant professor Mohammed Shafae is working to ensure 3D-printed parts achieve a higher standard of quality. In an article from the American Society of Mechanical Engineers, Shafae and assistant professor of materials science and engineering Andrew Wessman explain how they are developing a suite of sensors to monitor the printing process and detect when and where problems may occur.

3D printing anomalies can occur from "random variation" with the materials such as vaporization or cracking. The sensor suite, which includes thermal imaging and high-speed cameras, can better the process for printing jet engine parts.

“So for instance, say I have a lack-of-fusion defect,” Shafae said. “Can I change something when I make the next layer that helps to correct that defect? Can I add more energy on the next layer to melt a little bit deeper and fill in the hole, or should I terminate the process altogether? This kind of ‘correction mode’ is the long-term goal.”

“You’re never going to make a perfect part,” Wessman explained. “But in the aviation industry, we must understand the levels of imperfection that we can tolerate within the material.”